Spraying & Coating

Spraying & Coating

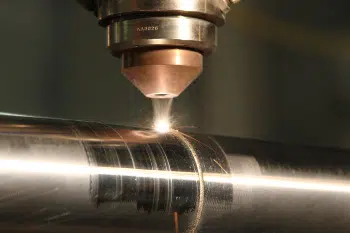

High-temperature plasma torches are widely used for plasma spraying and application of all kinds of coatings, including refractory materials.

Plasma spraying is effective for:

- Repair of worn-out parts and components of machines, including crankshafts.

- Creation of bimetallic products.

- Application of non-ferrous metal coatings on steel substrates.

- Creation of heat-resistant and hard ceramic coatings on metal and polymer bases.

- Application of carbides and oxides, including ceramics.

- Application of wear-resistant and anti-corrosion coatings.

Powder or wire of the sprayed material is fed to the high-temperature plasma flow. The molten material, blown onto the substrate at high speed, sticks to it, spreading over the surface. There, it quickly cools down, creating a protective coating.

Did not find what you need?

Let our experts help you.

Send your request now >