Plasma generation

More than 100 years have passed since the invention of plasma generators. Yet, it took another half a century until plasma-based technology made its way into the industry. Since then, plasma cutting has become a champion of plasma technology application. Notwithstanding, even these days, “plasma cutting” sounds like science fiction.

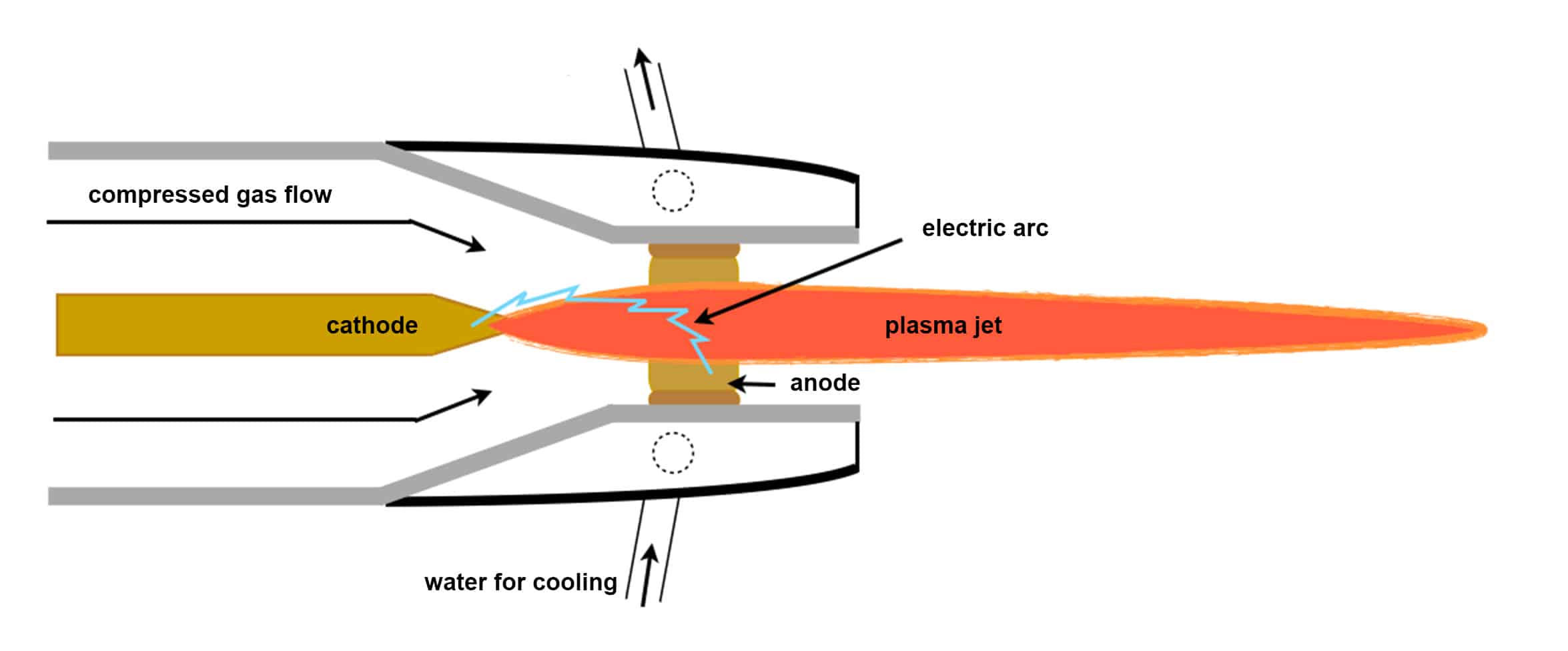

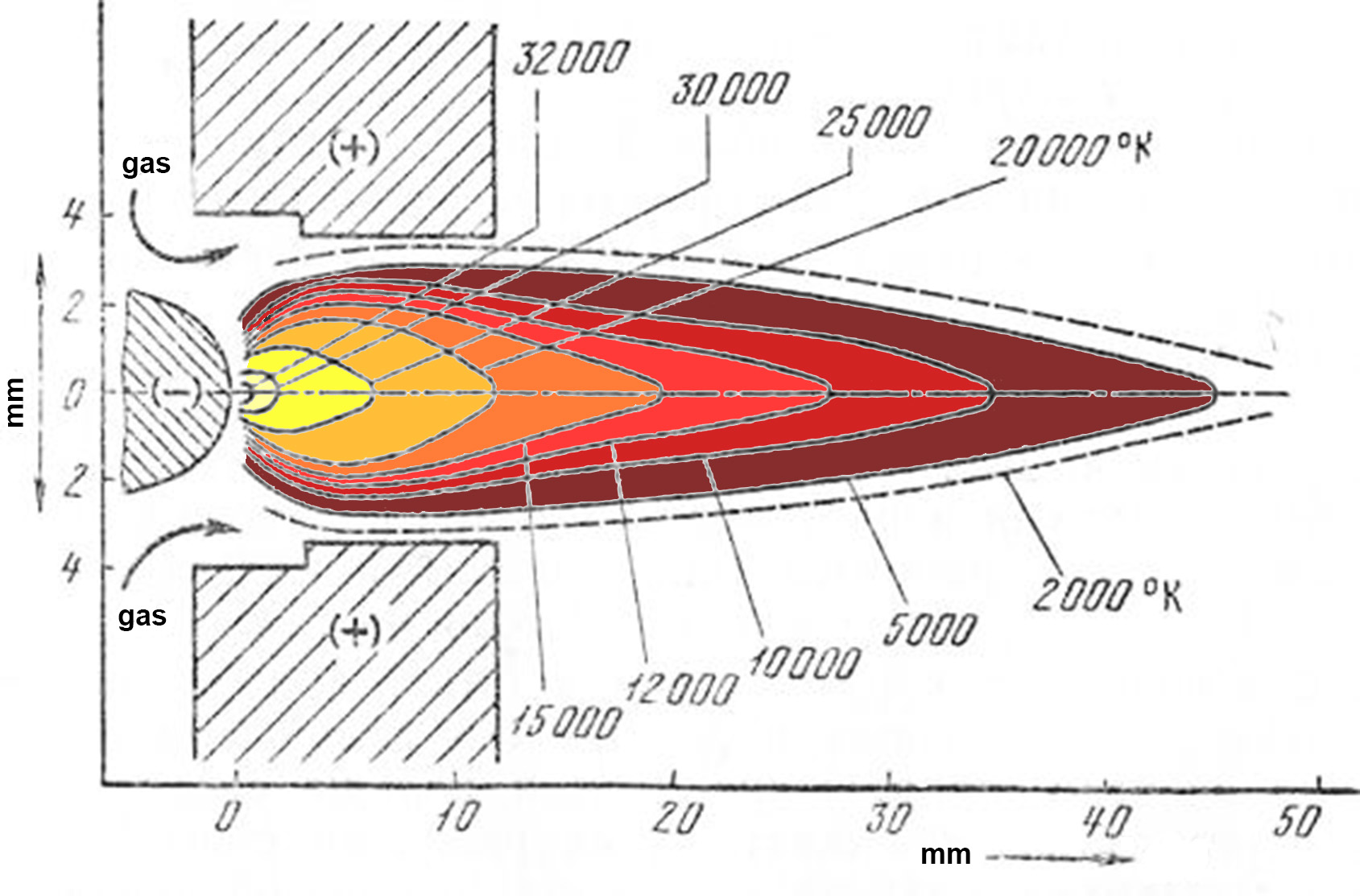

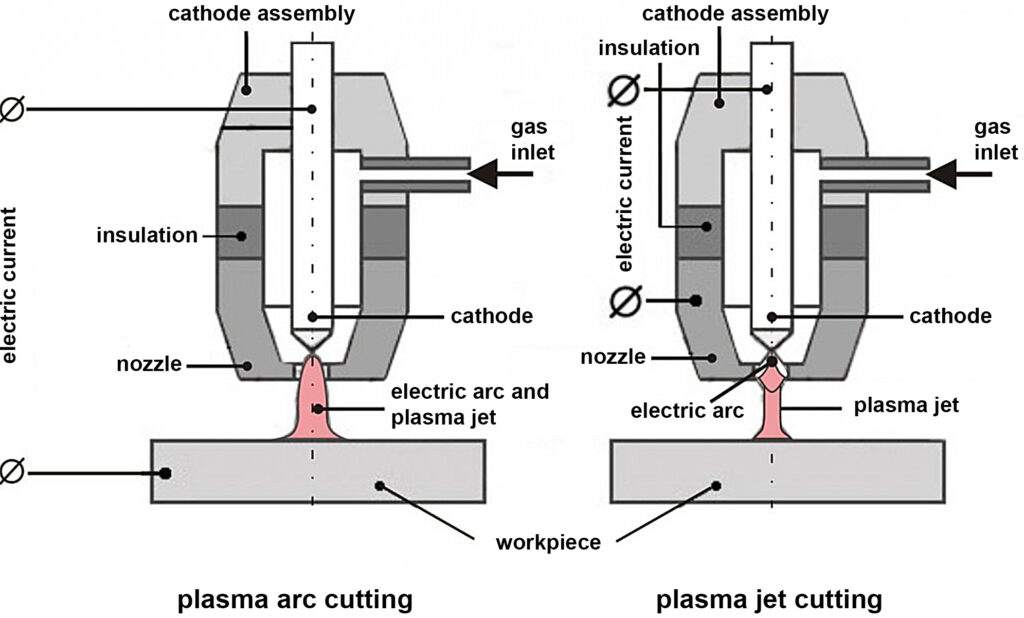

Plasma is an ionized gas wherein some of its molecules are positively charged ions due to loss of electrons. We can generate plasma in several ways, including subjecting gas to extreme temperatures or strong electromagnetic fields. In plasma cutters, plasma is generated by blowing a compressed gas through an electric arc. This gas can be nitrogen, argon, carbon dioxide, or even air. A freely burning electric arc has a temperature of 6000 – 8000 K. By increasing the gas flow rate, the electric arc becomes compressed, the arc temperature rises to 20,000 K. This temperature liberates electrons from gas molecules turning gas into the so-called “low temperature” plasma. Therefore the electrical energy is converted into the thermal energy of the plasma. These plasma generators are often called “plasmatrons”. Due to the plasma being electrically conductive, an electric arc is carried along with the plasma flow and transferred to a metallic workpiece. This high-temperature transferred arc does the cutting. When the workpiece is not conductive, the cutting can be done by the plasma jet itself. The molten material is removed from the cutting zone by the heated gas stream. Since the plasma temperature reaches tens of thousands of degrees, cutting even thick metals is incredibly fast. Also, unlike in oxy-fuel cutting, there is no need for a preliminary heating of metal.

Plasma is an ionized gas wherein some of its molecules are positively charged ions due to loss of electrons. We can generate plasma in several ways, including subjecting gas to extreme temperatures or strong electromagnetic fields. In plasma cutters, plasma is generated by blowing a compressed gas through an electric arc. This gas can be nitrogen, argon, carbon dioxide, or even air. A freely burning electric arc has a temperature of 6000 – 8000 K. By increasing the gas flow rate, the electric arc becomes compressed, the arc temperature rises to 20,000 K. This temperature liberates electrons from gas molecules turning gas into the so-called “low temperature” plasma. Therefore the electrical energy is converted into the thermal energy of the plasma. These plasma generators are often called “plasmatrons”. Due to the plasma being electrically conductive, an electric arc is carried along with the plasma flow and transferred to a metallic workpiece. This high-temperature transferred arc does the cutting. When the workpiece is not conductive, the cutting can be done by the plasma jet itself. The molten material is removed from the cutting zone by the heated gas stream. Since the plasma temperature reaches tens of thousands of degrees, cutting even thick metals is incredibly fast. Also, unlike in oxy-fuel cutting, there is no need for a preliminary heating of metal.

Over the years of development, plasma cutters became increasingly mobile and cheaper to operate. Also, plasmatrons became more reliable, less complex, and decreased in size, not the Jedi sabers yet but in the same ballpark. Nowadays, plasma cutting is one of the most economical, fast, simple, safe, and reliable thermal cutting equipment capable of producing high-quality cuts in a wide range of materials in the blink of an eye. When cut quality, productivity, and operating costs matter, these are good reasons to opt for a plasma cutting machine.

Over the years of development, plasma cutters became increasingly mobile and cheaper to operate. Also, plasmatrons became more reliable, less complex, and decreased in size, not the Jedi sabers yet but in the same ballpark. Nowadays, plasma cutting is one of the most economical, fast, simple, safe, and reliable thermal cutting equipment capable of producing high-quality cuts in a wide range of materials in the blink of an eye. When cut quality, productivity, and operating costs matter, these are good reasons to opt for a plasma cutting machine.

Useful links